The Great Laxey Wheel holds the title of being the largest working water wheel in the world! Measuring 72 feet and 6 inches, with 96 steps to the top, it’s an impressive example of Victorian era engineering and makes for an extraordinary tourist attraction today.

Why Was it Built?

The wheel was designed by local engineer Robert Casement to pump water out of the Laxey Mines complex, due to a significant flooding problem. It wasn’t the only wheel pumping water out of the complex, but it was the biggest and most impressive!

The grand opening of the ‘Lady Isabella’, the official name of the Great Laxey Wheel, was on the 27th September 1954 and saw thousands flocking to see the wheel turn for the first time.

How it Worked

The wheel was powered by rainwater from the Laxey hillside, which was delivered by a network of lades and cisterns to the wheel.

The water entered from the top of the wheel tower and went into the 168 buckets that hung around the circumference of the wheel. The rotational power generated by the wheel’s movement drove a large rod, connected to a T-rocker at the top of the mine’s engine shaft. This changed the horizontal movement of the rod to the vertical movement of the pump rod in the mine shaft.

This pump would bring water that had flooded the lower levels of the mine up to the main adit, where it would drain out to the Laxey River and Sea.

History of the Great Laxey Mine

The Laxey Mine complex is known to have been worked from at least the 1780s, with The Laxey Mining Company formed in 1848.

Lead and zinc were the all-purpose metal of the Victorian era, making supplies in high demand, ones which the Laxey Mining Company could meet. At its height the company employed over 600 people, producing 2400 tons of lead ore and half of the zinc ore output of the UK!

The Great Laxey Mine was more than more than 670m deep and had three main shafts; the Welsh Shaft, the Dumbell’s Shaft, and the Engine Shaft. By the mid-1850s the Great Laxey Mine was the parent of many smaller mines, including; Snaefell, North Laxey, and Glen Roy.

Whilst incredibly profitable in its heyday, The Laxey Mining Company’s reports from the 1890s show that making money was becoming harder. Some of the best seams had been worked so hard that extracting ore was becoming harder and more expensive. What’s more, prices for ore were declining as new mining areas opened up around the world. This resulted in lots of miners moving to America or Africa where prospects were better.

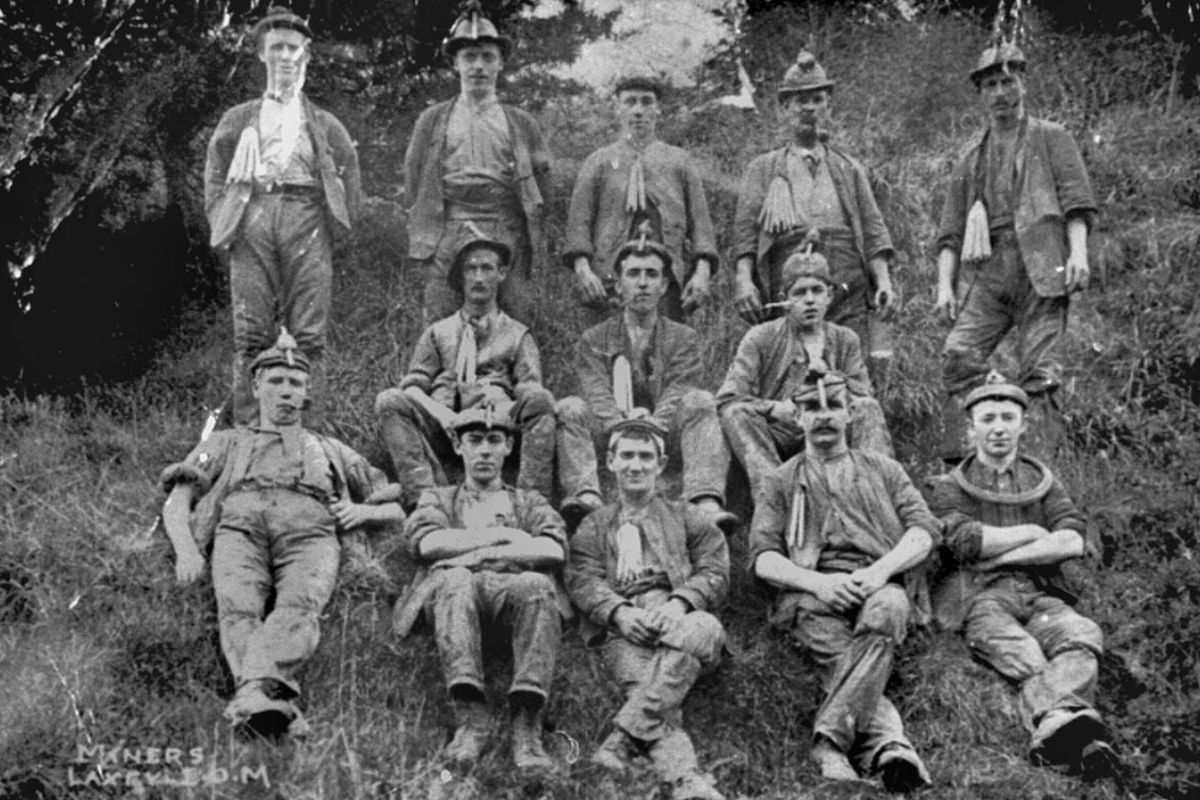

The Life of the Laxey Miners

The miners worked two shifts, one from 6am to 2pm and one from 2pm to 10pm, with many walking considerable distances to reach the mine. At the start of each shift they would face the long, slow descent into the mine via a series of ladders. Before going down the mine, each man would get a lump of softened clay, brought in carts from Clay Head, and place it on the front of his hard hat so that he could push a lit candle into it.

Conditions were considered good in the Laxey Mines. The men had a distance to walk once they had made their descent, but they could walk upright and were able to stand upright to work. Despite this, between 1831 and 1926 there were 36 deaths in the mines, alongside 55 serious accidents, commonly caused by gunpowder explosions, falling down shafts, being hit by falling rocks, or drowning.

The most deadly event to happen at the Laxey Mines was the Snaefell Mining Disaster that happened on the 10th May 1897. While the mine was closed on a Sunday, a pit prop, set alight by an unextinguished candle, smouldered and filled the shafts with poisonous carbon monoxide. As miners descended they were overwhelmed by the deadly gas. Of the 34 men who went into the mine that day, only 14 survived. The survivors managed to struggle back to the surface, but others didn’t have the strength and were very sadly killed. The photo above shows the rescue crew who were sent to recover bodies.

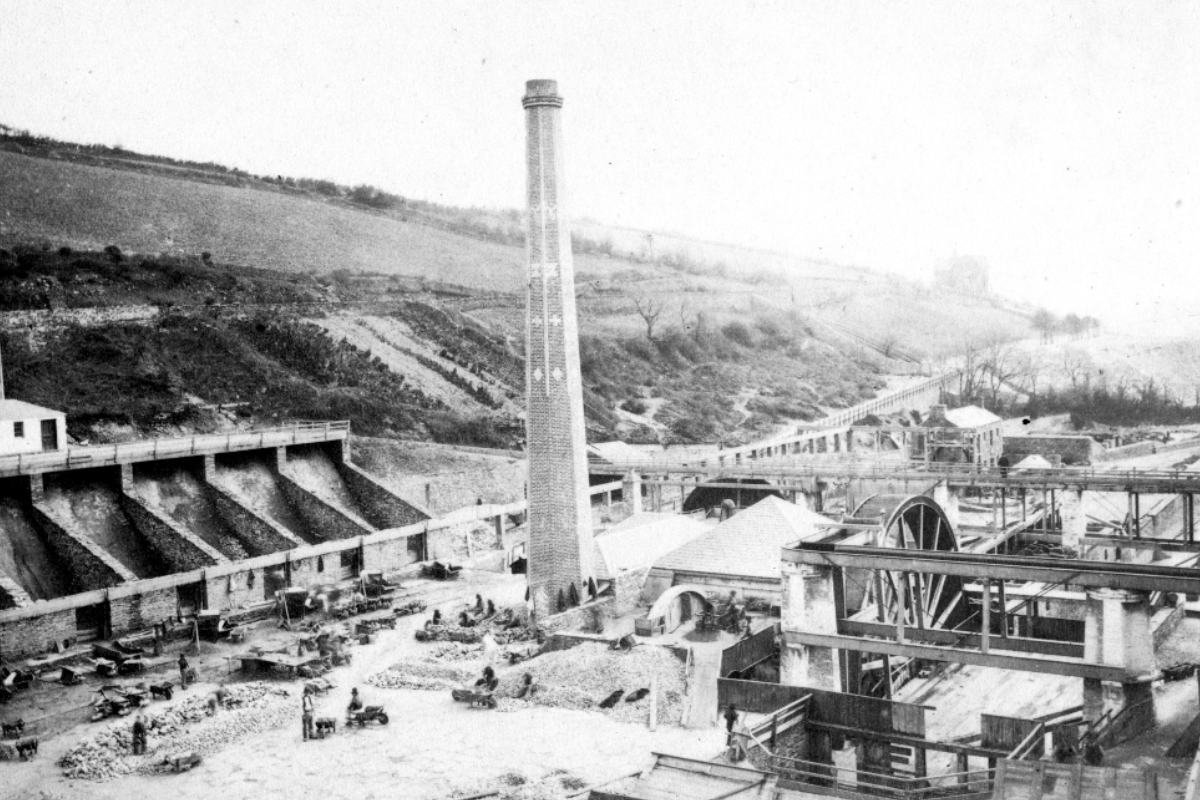

Surface Work at the Great Laxey Mine

It wasn’t just the miners who were employed by the Laxey Mining Company, many people, including women and children, were hired to complete surface work.

Surface work mainly took place on the Washing Floors, with nearly 300 people working there in the 1870s, where the process of separating the profitable ore from the waste stone took place. These materials were brought to the floors via the Laxey Mine Railway and were placed onto moving turntables where workers sat and sorted through them, a process known as ‘dressing’.

The metal was sent to the ‘crushers’ before being carried by horse tramway down Glen Road to Laxey Harbour and shipped to smelting works in Wales. The stone was sent to the ‘deads’, meaning it was tipped onto a large pile that eventually grew to tower above the adjacent houses! It was finally removed during World War 2 and used to create runways at two RAF stations in the north of the Island.

Conservation of the Great Laxey Wheel

.png)

Manx National Heritage are undertaking great conservation works at the Laxey Wheel. The first phase saw old render and decaying timbers replaced, ironmongery repaired, and the wheel housing, railings and viewing platform repainted. The latest phase of works includes repointing and repainting the wheel’s rod duct and the T-rocker, rods, bogies, associated timbers and iron works repaired and ready to power the wheel once again.

You can find out more about visiting the Great Laxey Wheel here.

Comments

Comments are disabled for this post.